tt

tt

tt

tt

tt

tt

Technology

•

May 20, 2025

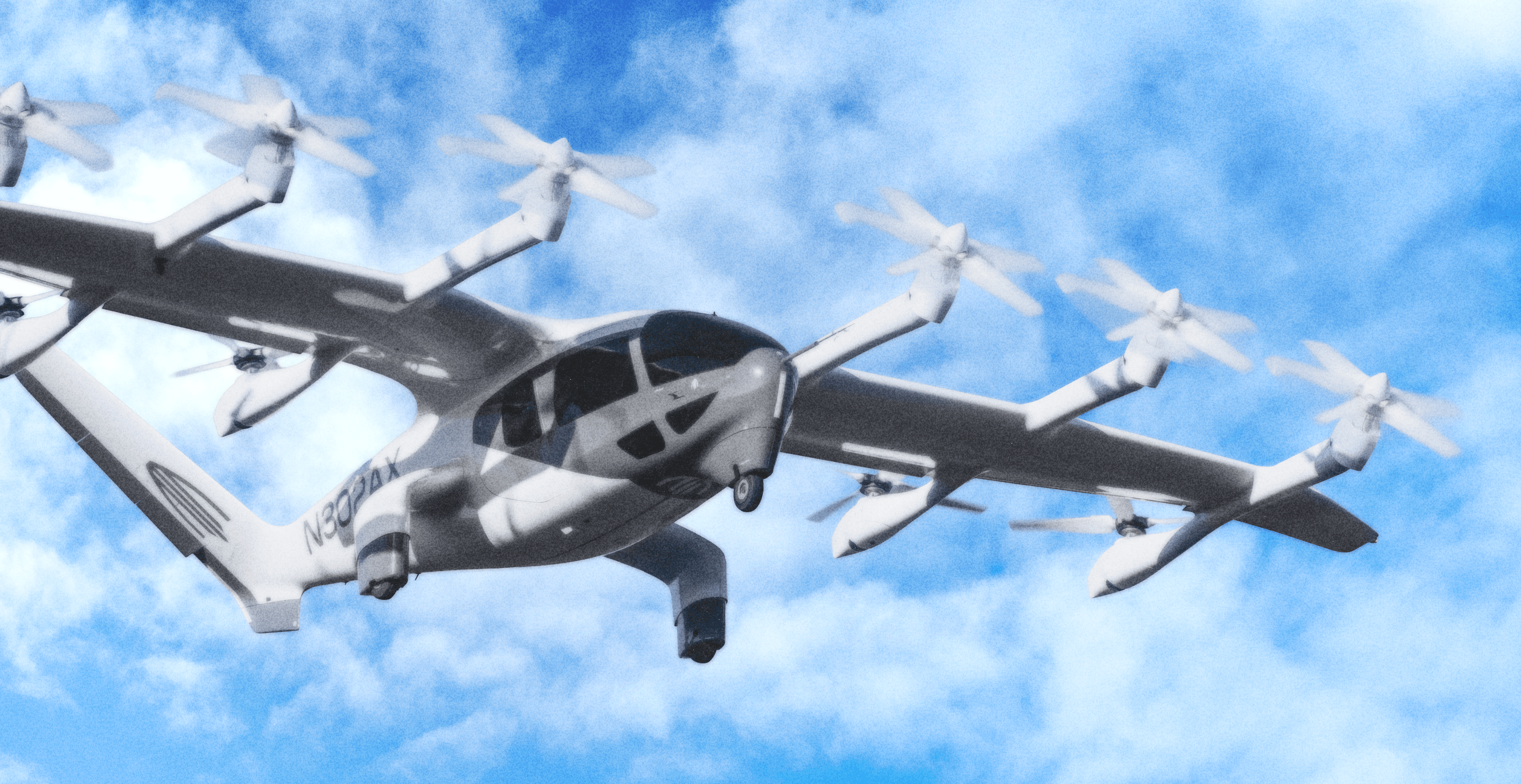

The Sea Monster that Flew

Poseidon Aerospace wants to resurrect a technological dream.

Sign in to keep reading

Sign up for free to see the rest of the article.

About the Author

Zaitoon Zafar is a junior editor at Arena Magazine. She can be found on X at: @zaitoonx.

ComponentTest